Manufacturing Process

|

Process of Making Hyakusogan

|

|

|

|

▼

|

② Blending Process ② Blending ProcessHyakusogan is a combination of Phellodendron Bark Extract、Powdered Geranium Herb、Powdered Atractylodes Rhizome、Powdered Zedoary、 Powdered Japanese Gentian 、Powdered Swertia Herb. 5 kinds of powdered herbal medicines are combined evenly with Phellodendron Bark extract by a blending machine. |

|

▼

|

③ Rounding Process ③ Rounding ProcessPills are manufactured by a rounding machine. We follow the procedure to start the rounding machine, adjust when necessary under the experienced technician’s supervision to manufacture fine-shaped pills. |

|

▼

|

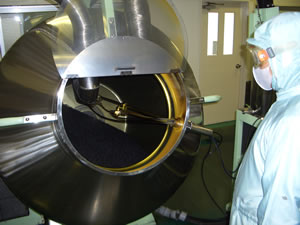

④ Finishing Process ④ Finishing Process After pills are manufactured by a rounding machine, their surfaces are treated. The coating device is used to coat Phellodendron Bark extract tincture on the surfaces of the pills so that the “bitterness” of Phellodendron Bark, unique to herbal medicine is emphasized. |

|

▼

|

⑤ Packing Process ⑤ Packing Process During the finishing process, the pills are filled in bottles or film packs, and then packed in the paper boxes. |

We have a very strict quality control so that our customers feel safe with our products. We intend to devote ourselves to provide our customers with trusted products.

① Extraction and concentration process of Phellodendron Bark extract

① Extraction and concentration process of Phellodendron Bark extract